XLPE Cable Explained: Meaning, Uses, and Material Comparison

2025-12-23What Is an XLPE Cable?

This section defines what an XLPE cable is, clarifies the acronym, and explains how XLPE insulation fits into cable construction. If your doubt is “XLPE cable meaning/define,” the goal is to give a clear definition first, then add the minimum technical context needed to understand why XLPE is used in real-world power and industrial wiring.

XLPE Cable Meaning and Definition

XLPE stands for Cross-Linked Polyethylene. An XLPE cable is an electrical cable whose conductor insulation is made from polyethylene that has been “cross-linked” to form a three-dimensional molecular network. In practical terms, cross-linking turns the insulation into a thermoset-like structure that resists softening and deformation at elevated temperatures better than standard (non-cross-linked) polyethylene.

A simple way to interpret the definition is: the conductor carries current, and the XLPE layer is the primary barrier that prevents current leakage, electrical breakdown, and insulation failure under heat and electrical stress. For many power cable designs, a typical continuous conductor temperature rating associated with XLPE insulation is 90°C, with short-circuit tolerance commonly referenced around 250°C (for a few seconds)—values that help explain why XLPE is frequently selected for higher-load applications.

- “Meaning” focus: XLPE describes the insulation material (cross-linked polyethylene), not the conductor metal.

- “Cable” focus: in practice, XLPE is usually part of a multi-layer system (insulation plus optional shield/screen and outer sheath).

- Quick takeaway: XLPE cable = cable insulated with cross-linked polyethylene, valued for stability under higher temperature and electrical stress.

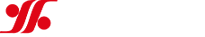

Key Components of an XLPE Cable

This subsection explains what you are actually buying when you see “XLPE” on a datasheet. “XLPE” typically refers to the insulation layer; the rest of the cable (conductor type, shielding, and sheath material) depends on the application (building wiring, industrial feeders, medium-voltage distribution, underground installation, etc.).

- Conductor (copper or aluminum): carries current; sized by cross-sectional area to meet ampacity and voltage-drop requirements.

- XLPE insulation: primary dielectric layer that provides electrical isolation and contributes to thermal performance.

- Semiconductive screens/shields (common in MV/HV designs): manage electric field distribution and reduce partial discharge risk.

- Metallic screen/armor (application-dependent): improves fault current handling and/or mechanical protection (e.g., underground or industrial environments).

- Outer sheath/jacket (often PVC, PE, LSZH, etc.): environmental and mechanical protection (abrasion, moisture, oils/chemicals, sunlight depending on compound).

| Context | Common voltage class examples | Why XLPE is used |

|---|---|---|

| Low-voltage power | 0.6/1 kV (common building/industrial feeders) | Higher continuous temperature rating can support higher current carrying capacity in similar conductor sizes. |

| Medium-voltage distribution | 6/10 kV, 12/20 kV, 18/30 kV (common MV classes) | Strong dielectric performance and field control compatibility (screened constructions) for MV networks. |

| High-load industrial service | Depends on facility design (LV or MV) | Thermal stability (often cited as 90°C continuous) improves reliability under sustained loading. |

In short, the defining feature of an XLPE cable is the insulation material and its performance under thermal and electrical stress. The next sections (in your outline) should build on this definition by explaining how cross-linking changes insulation behavior and then moving into use cases and comparisons against XLPO and PVC.

How XLPE Insulation Works

This section explains the functional mechanism behind XLPE insulation. Rather than redefining XLPE, the focus here is on how the cross-linking process changes insulation behavior and why those changes directly affect electrical reliability, thermal endurance, and long-term cable performance.

Cross-Linking Process in Polyethylene

In standard polyethylene insulation, polymer chains are largely independent and can slide past one another when exposed to heat. Cross-linking introduces permanent bonds between these chains, creating a three-dimensional network. This network structure prevents the material from flowing or melting once formed, even when temperatures rise close to its thermal limits.

From a functional perspective, this means XLPE insulation behaves less like a thermoplastic and more like a thermoset material. As a result, when current load increases and conductor temperature rises, the insulation is far less likely to soften, deform, or lose dimensional stability—an important factor in maintaining consistent insulation thickness and electric field distribution.

- Cross-linking converts polyethylene into a network structure that does not re-melt under normal operating temperatures.

- Dimensional stability of the insulation helps maintain predictable electrical performance over time.

- The process directly supports higher allowable operating temperatures compared with non-cross-linked materials.

Electrical and Thermal Properties of XLPE

The cross-linked molecular structure of XLPE has measurable consequences for both electrical insulation performance and heat resistance. In cable engineering terms, these properties influence insulation thickness design, ampacity calculations, and expected service life.

| Property | Functional meaning | Why it matters |

|---|---|---|

| Thermal endurance | Continuous operation commonly rated around 90°C | Supports higher current loading without premature insulation degradation. |

| Dielectric strength | High resistance to electrical breakdown | Allows reliable insulation performance at low, medium, and high voltage levels. |

| Thermal aging resistance | Slower property loss under prolonged heat exposure | Contributes to longer service life in continuously loaded installations. |

In functional terms, XLPE insulation works by maintaining its electrical and mechanical integrity under conditions that would cause conventional thermoplastic insulation to soften or age more rapidly. This performance foundation explains why XLPE is widely specified for power transmission, distribution, and other high-demand applications discussed in the next section.

What Is XLPE Cable Used For?

This section addresses the practical intent behind “what is XLPE cable used for.” Rather than focusing on material theory, the purpose here is to connect XLPE insulation characteristics to real installation scenarios, explaining where XLPE cables are commonly deployed and what functional problems they are designed to solve.

Power Transmission and Distribution Applications

XLPE cables are widely used in power transmission and distribution systems because their insulation performance supports higher electrical stress and sustained current loading. In utility and grid environments, reliability under continuous operation and fault conditions is a primary design requirement.

- Medium-voltage distribution networks: XLPE is a standard insulation choice for underground and overhead feeders supplying industrial zones and urban areas.

- Substation interconnections: used between transformers, switchgear, and outgoing feeders where electrical stress and thermal loading are significant.

- Renewable energy grid connections: commonly specified for wind and solar plants where fluctuating loads and outdoor installation conditions are expected.

In these applications, the ability of XLPE insulation to operate continuously at elevated temperatures allows engineers to design systems with higher current-carrying capacity or reduced conductor size compared with lower-temperature insulation options, depending on project priorities.

Industrial and Commercial Uses

Beyond utility grids, XLPE cables are widely used in industrial plants and commercial buildings where electrical loads are dense and operating conditions are demanding. In these environments, insulation stability directly affects uptime, safety, and maintenance cycles.

- Manufacturing facilities: XLPE cables are used for feeders supplying motors, production lines, and heavy equipment that generate sustained heat during operation.

- Commercial buildings and infrastructure: shopping centers, data centers, and transport hubs often specify XLPE-insulated power cables for main distribution circuits.

- Energy and utility plants: including power stations, water treatment facilities, and oil & gas installations where reliability under continuous load is critical.

| Application environment | Electrical demand profile | Why XLPE fits |

|---|---|---|

| Industrial plants | High continuous load, frequent start-up currents | Thermal stability supports long operating hours without insulation fatigue. |

| Commercial power distribution | Mixed loads, space-constrained installations | Higher temperature rating allows efficient use of conductor cross-section. |

| Outdoor / underground systems | Environmental and thermal stress | Stable insulation behavior under combined electrical and thermal stress. |

In summary, XLPE cables are used wherever electrical systems demand higher load capability, long-term reliability, and predictable insulation performance. These application-driven requirements set the context for the next section, which explains why engineers may deliberately choose XLPE over other insulation materials rather than using it by default.

Why Choose XLPE Cable?

This section explains the decision logic behind selecting XLPE cables. The objective is not to restate where XLPE is used, but to clarify why engineers and project planners deliberately choose XLPE when evaluating insulation options for performance, safety margins, and lifecycle value.

Advantages of XLPE Cable

The primary reasons for choosing XLPE cable are tied to how its insulation behaves under electrical load, heat, and long-term service conditions. These advantages often translate directly into system-level benefits such as improved reliability or more efficient design.

- Higher current-carrying capability: the higher allowable operating temperature enables either increased ampacity or reduced conductor size in comparable installations.

- Improved electrical reliability: stable insulation geometry helps maintain consistent electric field distribution, reducing the risk of insulation breakdown.

- Longer service life under load: resistance to thermal aging supports extended operating periods without frequent replacement.

- Broad voltage applicability: XLPE is suitable for low-, medium-, and high-voltage designs, simplifying material standardization across projects.

In practical design scenarios, these advantages allow engineers to balance safety margins and efficiency. For example, in space-constrained cable trays or ducts, the ability to safely operate at higher temperatures can be a decisive factor when selecting XLPE insulation.

Limitations and Design Considerations

Despite its advantages, XLPE is not automatically the best choice for every application. Understanding its limitations ensures that insulation selection remains technically justified rather than habitual.

- Higher initial cost: XLPE cables are typically more expensive than basic thermoplastic-insulated alternatives, which may impact budget-sensitive projects.

- Installation discipline: improper bending radius, pulling tension, or termination practices can compromise insulation performance, especially in medium-voltage systems.

- Environmental pairing required: while XLPE performs well electrically, the outer sheath material must still be selected correctly to handle UV exposure, chemicals, or moisture.

| Design factor | Why it favors XLPE | When to reassess |

|---|---|---|

| Thermal loading | Handles sustained high temperatures reliably | Low-load circuits with minimal heat generation |

| Service life expectations | Supports long-term continuous operation | Temporary or short-duration installations |

| Cost sensitivity | Lifecycle value offsets higher upfront cost | Projects driven primarily by lowest initial price |

In essence, XLPE cable is chosen when performance, durability, and thermal margin outweigh initial material cost. This trade-off becomes clearer when XLPE is directly compared with alternative insulation materials such as XLPO and PVC, which is addressed in the following sections.

XLPE vs XLPO Cable

This section clarifies a common point of confusion by comparing XLPE with XLPO cable insulation. Although both materials are cross-linked polymers, they are optimized for different performance priorities. The purpose here is to distinguish their functional roles rather than to position one as universally superior.

What Is XLPO Cable?

XLPO stands for Cross-Linked Polyolefin. Unlike XLPE, which is primarily engineered for electrical insulation in power cables, XLPO is typically formulated to emphasize flexibility, flame performance, and low-smoke characteristics. As a result, XLPO is most commonly found in control cables, appliance wiring, automotive harnesses, and applications where fire safety and handling ease are critical.

Functionally, XLPO insulation is still cross-linked, meaning it benefits from improved thermal stability compared with non-cross-linked plastics. However, its electrical performance profile is generally designed for lower voltage and signal-level applications rather than medium- or high-voltage power transmission.

XLPE vs XLPO: Key Differences

The most meaningful differences between XLPE and XLPO appear when comparing electrical stress capability, mechanical behavior, and typical use environments. These differences explain why the two materials rarely compete directly in the same specifications.

| Comparison factor | XLPE cable | XLPO cable |

|---|---|---|

| Primary design focus | Electrical insulation for power transmission | Flexibility and fire performance |

| Typical voltage range | Low to high voltage (including MV/HV) | Low voltage and signal/control circuits |

| Mechanical flexibility | Moderate | High |

| Fire and smoke behavior | Depends on sheath and compound formulation | Often formulated for low smoke and halogen-free performance |

When to Choose XLPE or XLPO

Selection between XLPE and XLPO should be driven by application demands rather than material familiarity. Each insulation serves a distinct engineering purpose.

- Choose XLPE when the cable must handle higher voltage levels, sustained current load, and long-term electrical stress.

- Choose XLPO when flexibility, flame retardancy, and low-smoke performance are more critical than high-voltage insulation strength.

- In mixed systems, it is common to see XLPE used for main power feeders and XLPO used for control or auxiliary wiring.

Understanding this distinction prevents misapplication and ensures that insulation choice aligns with system risk, safety objectives, and regulatory expectations. A similar comparison logic applies when evaluating XLPE against PVC insulation, which is addressed in the next section.

XLPE vs PVC Cable

This section compares XLPE with PVC insulation, the most widely used thermoplastic cable material. The goal is to explain why PVC remains common despite technical limitations and under what conditions XLPE provides a clear functional advantage, helping readers avoid assuming that one option automatically replaces the other.

Overview of PVC Cable Insulation

PVC (Polyvinyl Chloride) is a thermoplastic insulation material widely used in building wiring and general-purpose power cables. Its popularity is driven by low cost, ease of processing, and good mechanical toughness under normal ambient conditions.

Functionally, PVC insulation softens when exposed to higher temperatures. Typical continuous conductor temperature ratings are around 70°C for standard PVC compounds. This limitation does not make PVC unsuitable; rather, it defines the operational envelope within which PVC cables are reliably used.

Performance Comparison: XLPE vs PVC

The primary differences between XLPE and PVC appear in thermal behavior, electrical efficiency, and long-term aging. These differences influence conductor sizing, installation density, and expected maintenance intervals.

| Comparison factor | XLPE cable | PVC cable |

|---|---|---|

| Continuous temperature rating | ~90°C (commonly cited) | ~70°C (standard PVC) |

| Thermal aging behavior | Slower degradation under sustained heat | Faster property loss as temperature approaches limit |

| Electrical losses | Lower dielectric losses | Higher dielectric losses in comparison |

| Material cost | Higher initial cost | Lower initial cost |

Cost and Application Trade-Offs

Choosing between XLPE and PVC is often a cost–performance decision rather than a purely technical one. Many standards and projects continue to specify PVC where operating conditions remain well within its thermal and electrical limits.

- PVC is typically sufficient for residential wiring, light commercial circuits, and installations with low to moderate load density.

- XLPE becomes preferable where higher current density, elevated ambient temperature, or long continuous operation is expected.

- In many projects, designers justify XLPE by lifecycle value rather than initial purchase price alone.

In summary, PVC remains a practical and economical insulation for many everyday applications, while XLPE is selected when performance margins, efficiency, or service life are critical design drivers. Understanding this distinction helps ensure insulation choice is aligned with both technical requirements and project economics.

Summary: Choosing the Right Cable Insulation

This final section consolidates the earlier analysis into a practical selection framework. The purpose is to help readers move from understanding definitions and comparisons to making a clear, application-driven insulation choice based on technical and economic priorities.

Application-Based Selection Guide

Cable insulation selection should start with operating conditions rather than material preference. Factors such as load profile, ambient temperature, installation environment, and expected service life typically determine whether XLPE, XLPO, or PVC is the most appropriate option.

- For high-load or continuously operated power circuits, XLPE provides the thermal margin and electrical stability required for long-term reliability.

- For control, signal, or fire-safety–focused applications, XLPO may be preferred due to flexibility and low-smoke performance.

- For cost-sensitive and lightly loaded installations, PVC remains a widely accepted and standards-compliant solution.

| Primary priority | Recommended insulation | Rationale |

|---|---|---|

| Thermal and electrical performance | XLPE | Designed for higher temperature and voltage stress. |

| Fire behavior and flexibility | XLPO | Optimized for low-smoke and flexible installations. |

| Lowest initial cost | PVC | Economical and widely standardized for general use. |

Key Takeaways on XLPE Cable

XLPE cable should be viewed not as a default upgrade, but as a purpose-driven insulation choice. Its value lies in supporting higher electrical and thermal demands while maintaining predictable performance over long service periods.

When insulation selection aligns with actual operating conditions, XLPE, XLPO, and PVC can each serve their roles effectively. Understanding these distinctions allows designers, engineers, and buyers to specify cables that balance safety, performance, and cost—rather than relying on material labels alone.

Contact Us

Your email address will not be published. Required field are marked*

English

English 中文简体

中文简体 Español

Español عربى

عربى