1. Explosion Proof and High

Corrosion Resistance High Temperature Resistance Resistance to Mechanical ImpactAdvantages of MI Cable

Explosion Proof

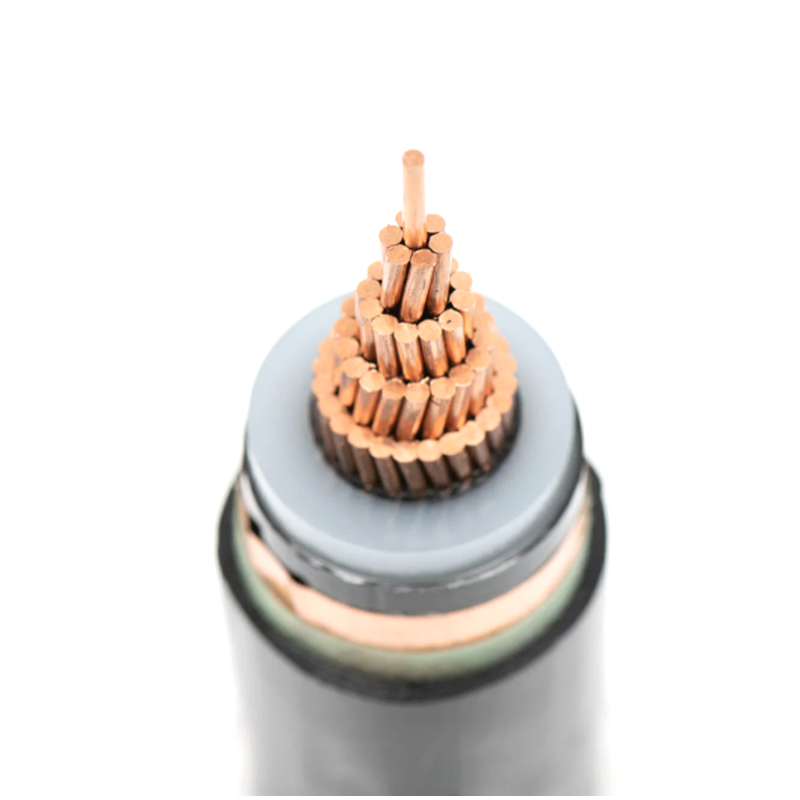

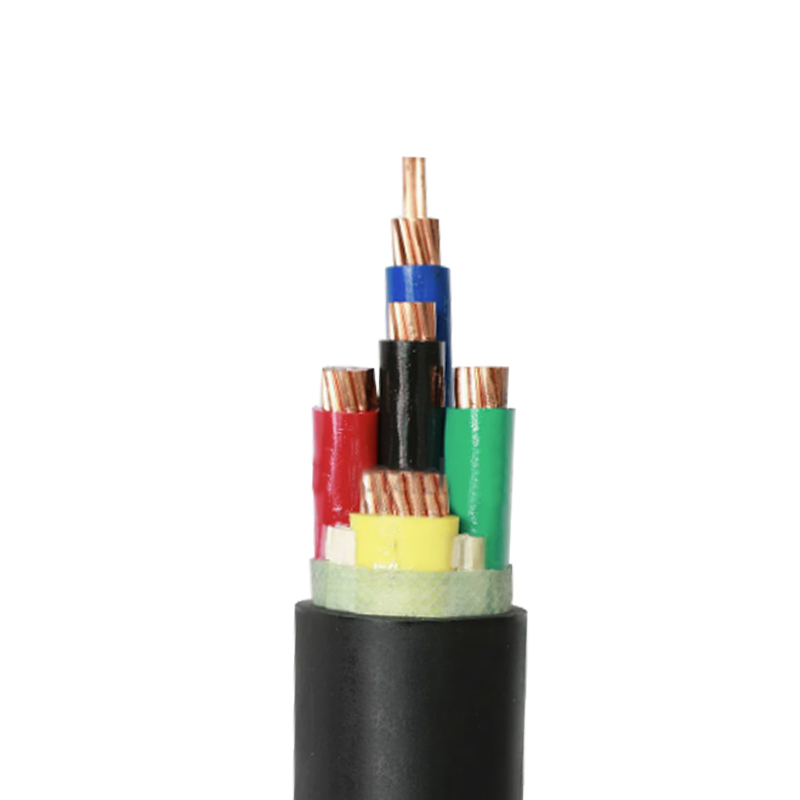

The MI cable is made up of seamless copper sheath,magnesium oxide powder compacted a tighly solid,Soit can prevent thesleam,gas and blaze into the electrical equipment connected with the cable.So it has the quality of explosion proof.

High Corosion Resislance

The copper sheath of MI cables has the self-character of high crrosion reaistance.Only in any area where would corrode thecopper,it must be covered with a PVC outer sheath to prevent the corrosion.

High Temperature Resistance

This cable works normally and continuously at 250℃ high temperature.works in a short time when it is close to 1083℃-the melingpoint of copper,and magnesia insulation material doesn't change in the nature.This characteristie is suitable to be used in metallurgyCement and other high temperature environment.

Resistance to Mechanicl Impact

Because conductor and metal sheath of the cable have good strength and toughnesB,and magnesium oxide is highly compactedduring Conductor,sheath and insulation constitutes a dense integral.The relative position between cores and betwen core and sheathkeps constant when suffering bending,wavering,toraion eteSo there is no shart-cireuit and electrice property can not be influenced.

2. Advantages of MI Cable

Small curve radius,small space required for laying

The mineral-insulated cable is of a compect body.wih a minimum curve radius les than orequivalent to 6D(D being the diameter of the cable).Therefore,the installation of the cable israthe easy and doesn't take much space,making it an ideal substitute for busways to be laidin places where small space is required.

NO Toxicity and Halogen-free

This cable totally consists of inorganic materials (copper and magnesia powder),So itdoesn't self-ignite,produce smokes or toxie gases when fire breaks out.Therefore,it is asafe and environment.friendly cable in the real sense.

High Oveload

Since this cable makes use of magnesia whose melting point is 2800℃,compared withordinary plastic cables,the current.carrying capacity of mineral insulated cable can beraised to a higher sectional level.At the same time.mineral insulated cable iS able to endurevery great overload.which can be over 10 times larger than normal current-carrying capacity.

Mineral insulated cable recovers quickly after over-voltage,and itsinsulation is notharmed.

Reduction of sheath

thickness (mm) |

250℃ |

400℃ |

800℃ |

| (Year) |

(Year) |

(Hour) |

| 25.4 |

2.57 |

0.0583 |

0.259 |

| 50.8 |

10.3 |

0.233 |

1.04 |

| 127.0 |

64.3 |

1.46 |

6.48 |

| 254.0 |

257 |

5.83 |

25.9 |

Long Service Life

Because MI cable is made up of inorganic material without ageing,we can compute itsl ife span according to oxide,elch velocily of copper tube.P9 It is reported that 0.25mmsheath willtake 257years to oxide elch under the condition of250℃,Also,the thicknes ofMl cable sheath is 0.31-1.17mm and operating temperature is under 250℃,so MI cable hasthe quality o long service life.

Copper Sheath as a Ground Wire

The MI cable is a good ground wire,for continuity and extremely low groundingresistance,When the copper sheath is used as the grounding wire,the crosB-section shouldcomply with the regulation of JGJ232-2011 Technical specification for the laying of mineralinsulated cables.

| Application:As MI cable has special performances,therefore can be used in fire circuit under 1000V as follows: |

| Fire extinguishing system |

Emergency lighting

Emergency broadcasting |

Emergency exits and escalators |

| Fire alarm control circuit |

Computer information center |

Refrigeration units |

| Power room transmitting circuit |

Constant power supply circuits |

Double power source system |

| Public lighting circuit |

Trunk and branch power distribution system |

Scenic spot and historic resort ligheing |

Power supply and high temperature

places and control circuit |

Oil pump circuits |

The circuit in environments where

potential explosion gases are present |

Product Technical Parameters

1. The rated voltage of mineral-insulated cables:light load(BTTQ、BTTVQ、WD-BTTYQ)500V and heavy load(BTTZ、BTTVZ、WD-BTTYZ)750V.

2. Testing voltage of mineral-insulated cables:light load 2000V/1min and heavy 2500V/1min.

3. The insulation resistance of mineral-insulation cables shall be more than 1000MW;when th length of cable is less than 1000m,theinsulateion resistance shall be more than 10,000MW.

4. Long-term service temperature of mineral-insulated cables:The long-term service temperature of mineral insulated cables is70℃.In areas inaccesible to people,the long-term service temperature is 105℃; in special high temperature circumstance,thelong-trem service temperature can reach 250℃.When the temperature keeps at 950-1000℃,the cable can sustain power supply forat leasl 3 hours;during a short or extremely short period, the service temperature can reach 1083℃.

5. Curve radius:The possible minimum curve radius of mineral-insulated cables shall be in line with the above form.

|

External diamter of the cable

D(mm)

|

D<7 |

7≤D<12 |

12≤D<12 |

D≥15 |

|

Minimum curve radius

R(mm)

|

2D |

3D |

4D |

6D |

36 Years of Experience

36 Years of Experience

Wide Range Of Products.

Wide Range Of Products.

Research and Development.

Research and Development.

English

English 中文简体

中文简体 Español

Español عربى

عربى